优质的解决方案

英瓦曼德的起重设备从60Kg到600吨甚至更大,可以满足客户各种工况的需求,为客户提供一站式的解决方案。我们在技术方面的持续创新、产品质量的稳步改进以及完善的服务体系帮助客户节省成本,提高效率,长期为客户创造价值。我们的起重设备涵盖了环链电动葫芦、钢丝绳电动葫芦、电动开放式卷扬机单双梁、桥式起重机、门式起重机、通用桥式起重机、柔性梁轻型起重机、悬臂吊、防爆葫芦、防爆起重机和手动产品等产品系列,能够为客户提供有竞争力的全套物流搬运解决方案。

产品中心

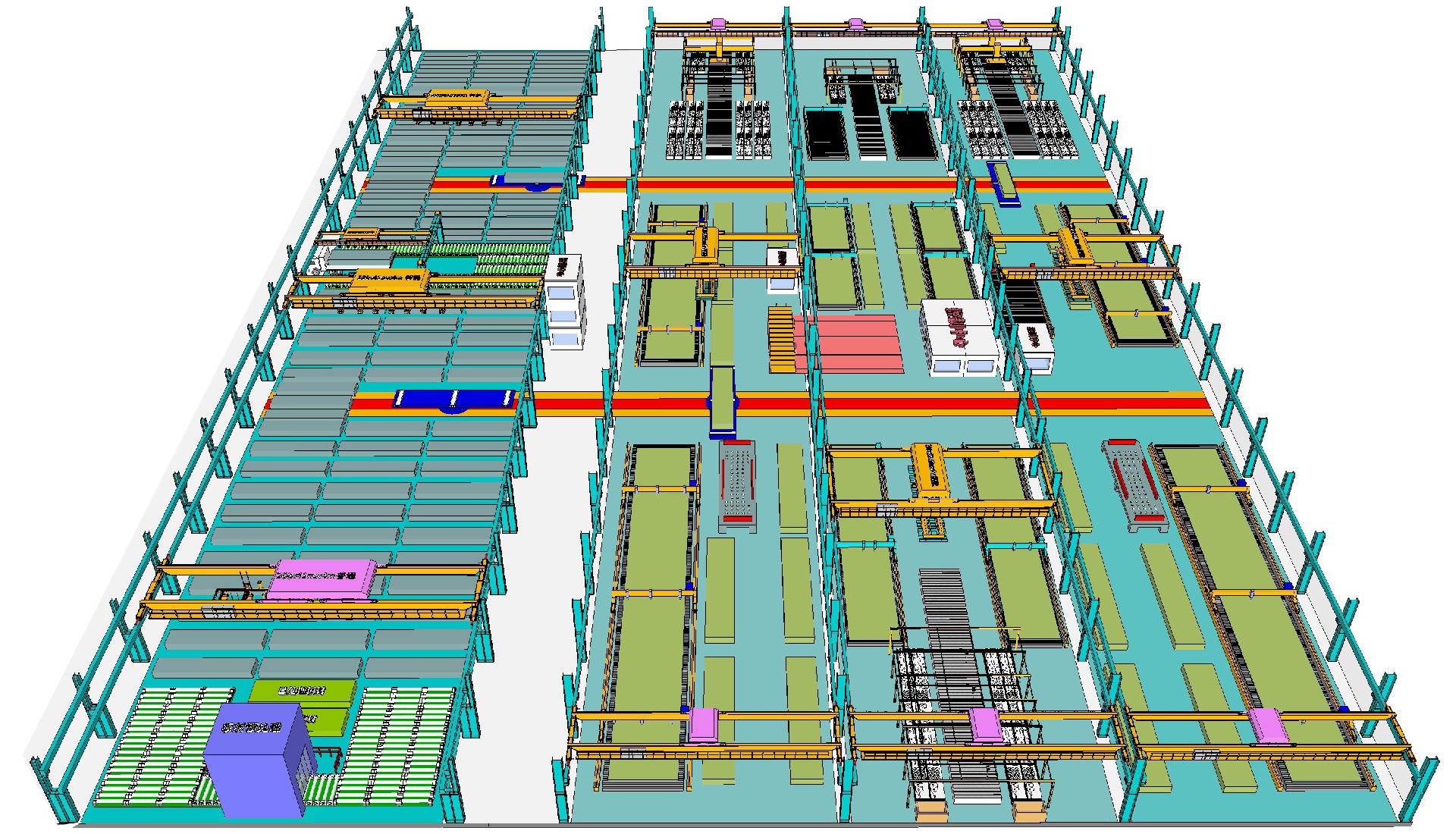

Fully automatic loading and unloading of magnetic intelligent cranes

All the advantages translate into economic benefits

Automation

EUROHOIST automatic control software is developed by the automation department of Ingvar Mende, which is mature and reliable, and has a high degree of freedom, and can be expanded according to different working conditions, and can be switched between fully automatic operation in normal operation and manual operation in emergency situations automatically. The optimal path for crane operation is calculated automatically by the PLC system through the software to control the automatic operation of the crane to complete a variety of operations and handling tasks (including loading/unloading/etc.), all operational tasks with high safety, high efficiency and high reliability, the three-dimensional positioning of the Intelligent Electromagnetic Crane of Inwamind, the lifting, trolley, trolley through the absolute value of the encoder and laser sensors to obtain, with high measurement accuracy, the control programme of the basic data source is more guaranteed.

Intelligent travelling crane (unmanned crane) is mainly used for the following movements of production line steel plates:

- Automatic transport from the infeed flat carriage to the cutting machine;

- Automatic transport from the infeed leveller to the temporary plate caching station;

- From the in-line plate caching station to the cutting machine;

- Palletising operations in the in-line plate caching station;

- After cutting, the whole steel plate (including parts and frames) on the cutting machine is automatically transported to the sorting platform.

Intelligent electromagnetic crane scheduling

Realise real-time monitoring of intelligent electromagnetic cranes and task scheduling of intelligent electromagnetic cranes, including warehousing, dispatching tasks, task feedback, exception handling, task stopping and deletion.

Product genealogy and traceability

Automatic tracking of material location, automatic tracking of material status, multiple information enquiry.

Operator Management

Dividing the functions and operation rights according to the different positions of operators, and automatically recording the operator's operation time, workload, and work process history.

Warehouse Management

It can carry out in-stock management, out-of-stock management, in-stock transfer management, and provide inventory management to carry out inventory manual counting intervention. Inventory query function is available.

It is possible to manage production stations, production lines, and equipment-side virtual libraries (cache libraries).

Logistics Management

Logistics task: Provide logistics task receiving, allocation, query, adjustment and other functions.

Logistics equipment scheduling: Provide logistics equipment scheduling management, including task acceptance, automated logistics equipment, manual logistics equipment, etc.

Maintenance Management

Provide crane equipment maintenance management catalogue, planning, maintenance, tracking and other functions.

Historical data management

Provide a complete set of historical data management functions.

Reliability

Provide hard disc redundancy technology to ensure data security, to cope with a large number of users accessing at the same time.

Security

Measures to ensure network security, access security, data security, and password security.

Usability

Achieve intelligent checking and intelligent prompting of input content.

Portability

Easy to install, client-side installation, update, and server-side deployment.

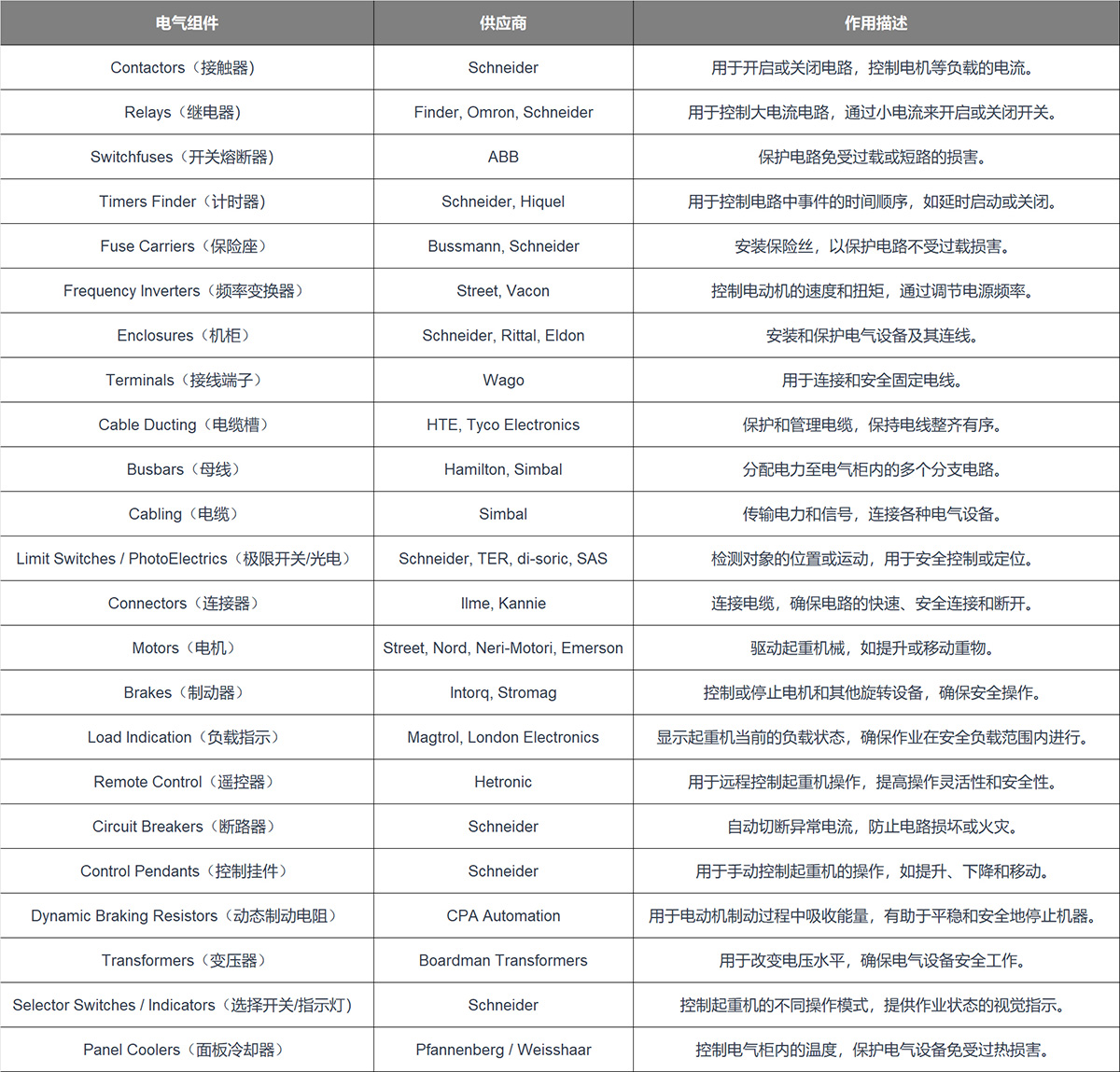

Selection of high quality electrical components

应用案例

销售热线

400-000-6926

Copyright 2024 英瓦曼德起重设备(上海)有限公司 All Rights Reserved. 沪ICP备16003943号-1 沪ICP备16003943号-2 沪公网安备31011202021147号

400-000-6926

400-000-6926

LANGUAGE

LANGUAGE